This scooter project was dreamed up as a material case study for Stratasys and Henkel to see what a soon-to-be-launched material was capable of, and to demonstrate just how easy Dura56 is to print on the Origin One. In just 81 days, we went from initial brainstorming, through three iterations, and then successfully created a finished product. All 3D printed parts, which consist of over 90% of the scooter’s mass, were printed in under 48 hours using 3 printers. Developed specifically for Origin® 3D printers, Dura56 is a durable, impact-resistant photopolymer with an exceptional surface finish and a low cost per kg. Weight reduction and FEA testing were done to inform the exterior shell geometry and the internal lattice systems. The major challenge was designing all 7 unique parts in parallel with sourcing existing hardware that would work to complete the overall scooter. Print orientation and strategic drainage holes proved to be very critical in the success and execution of this project in the short schedule it needed to be completed. Additionally, the deck is larger than the print volume made for some challenges in the assembly that were resolved with 3 structural slots & struts that were secured with barrel bolts.

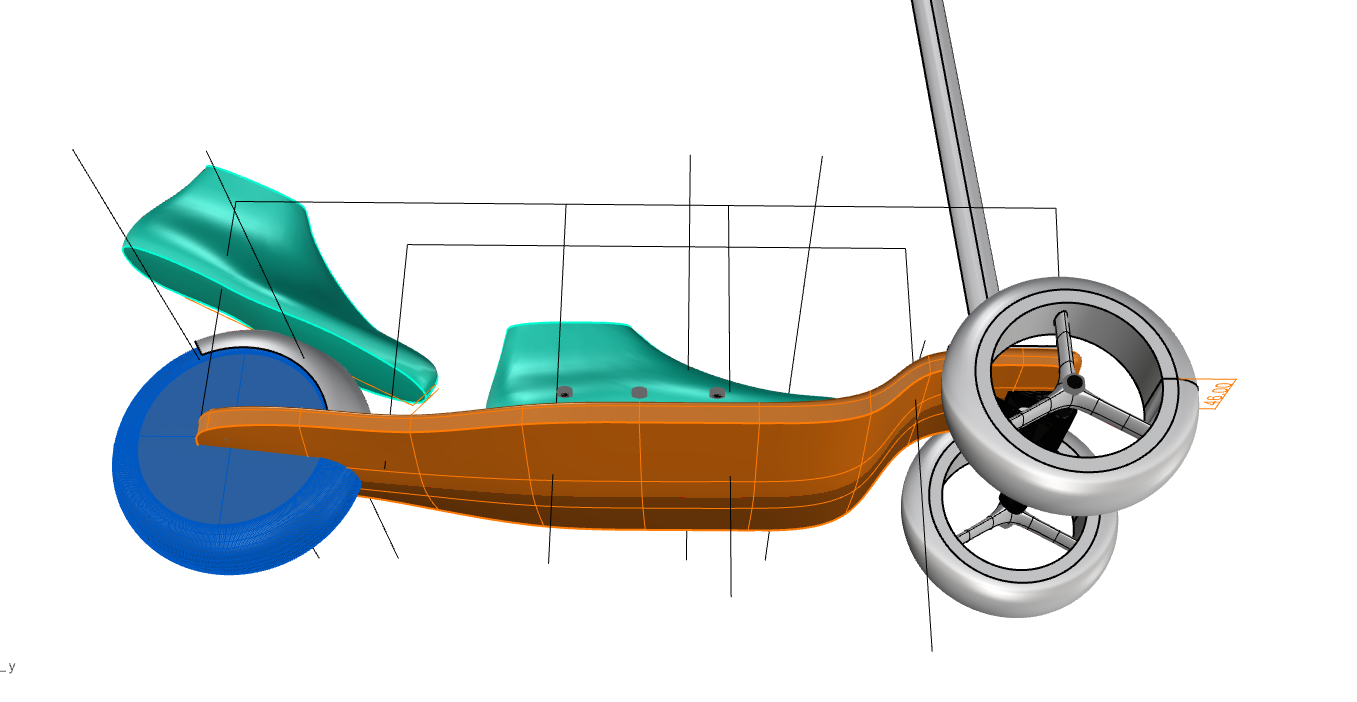

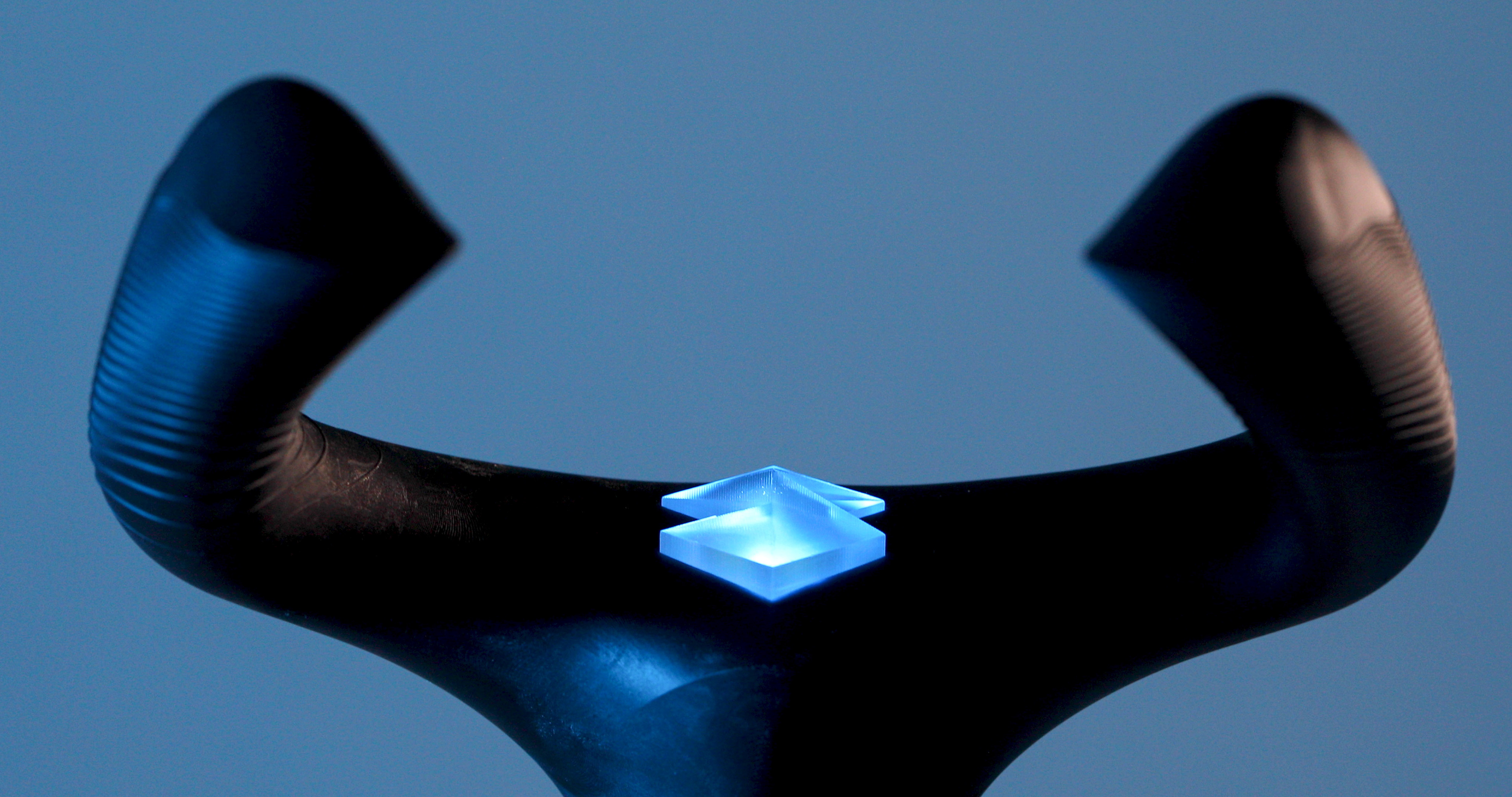

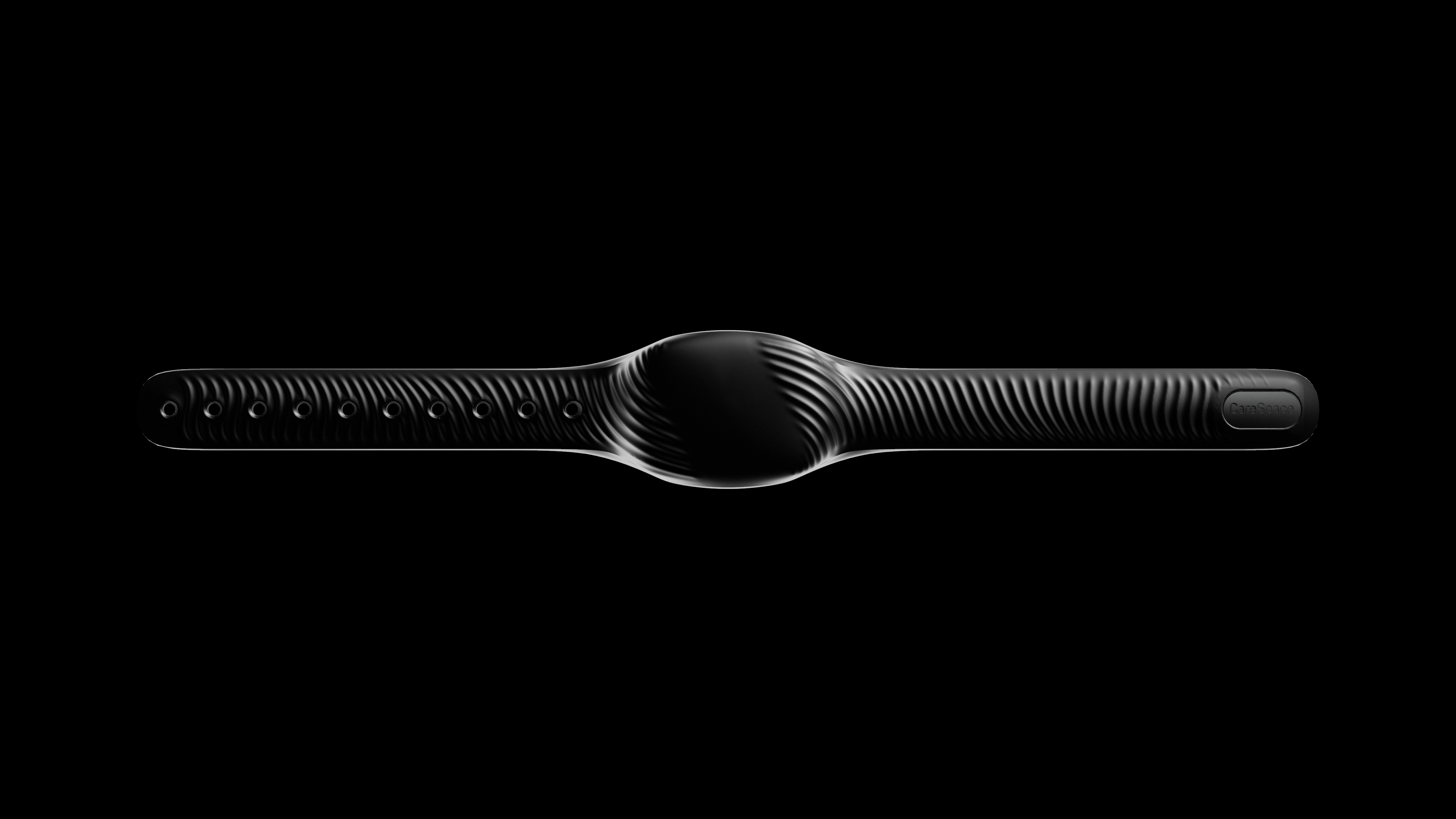

HANDLEBARS - 340cm3, 12.16h print time, $112 part cost.The lean-to-steer design offers excellent ergonomics and requires minimal supports to print.

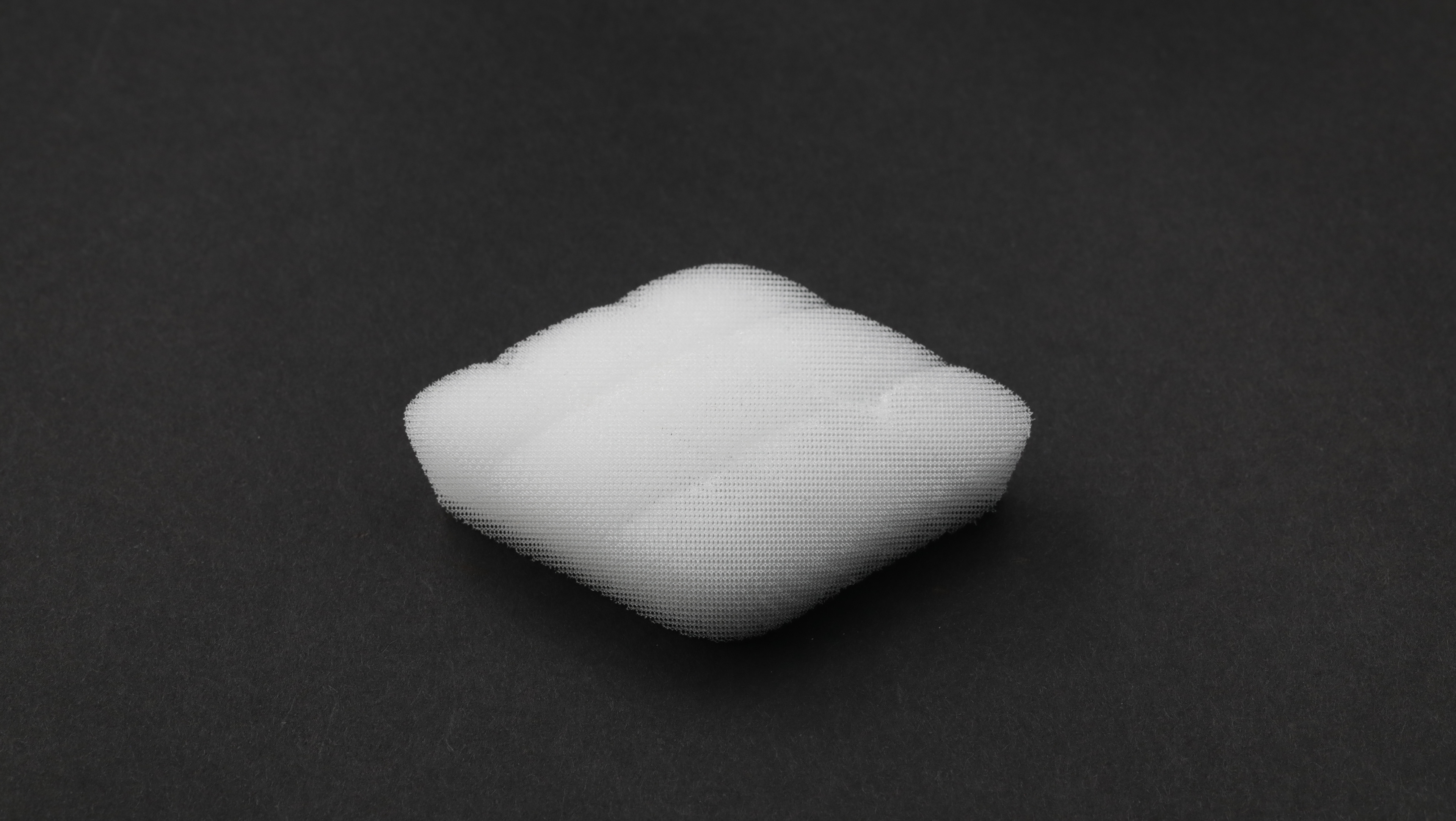

HEADLIGHT - 52cm3, 50m print time, $1.83 part cost. Refractive design printed with frosted transparent Loctite IND405 results in bright light with no added tint. This light is friction fit into a recess that houses an LED light.

REAR BRAKE - 123cm3, 8.83h print time, $27 part cost. Designed to withstand repeated flexion & friction in use.

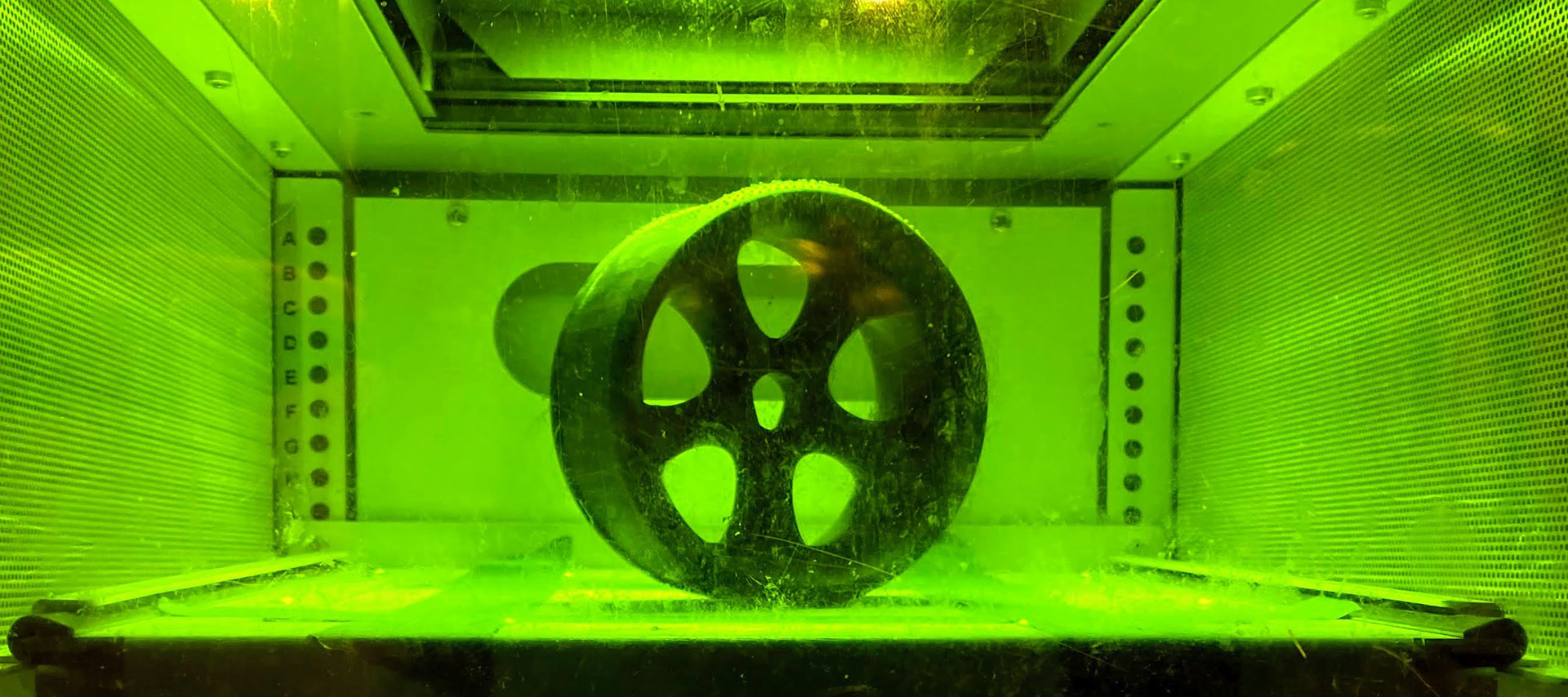

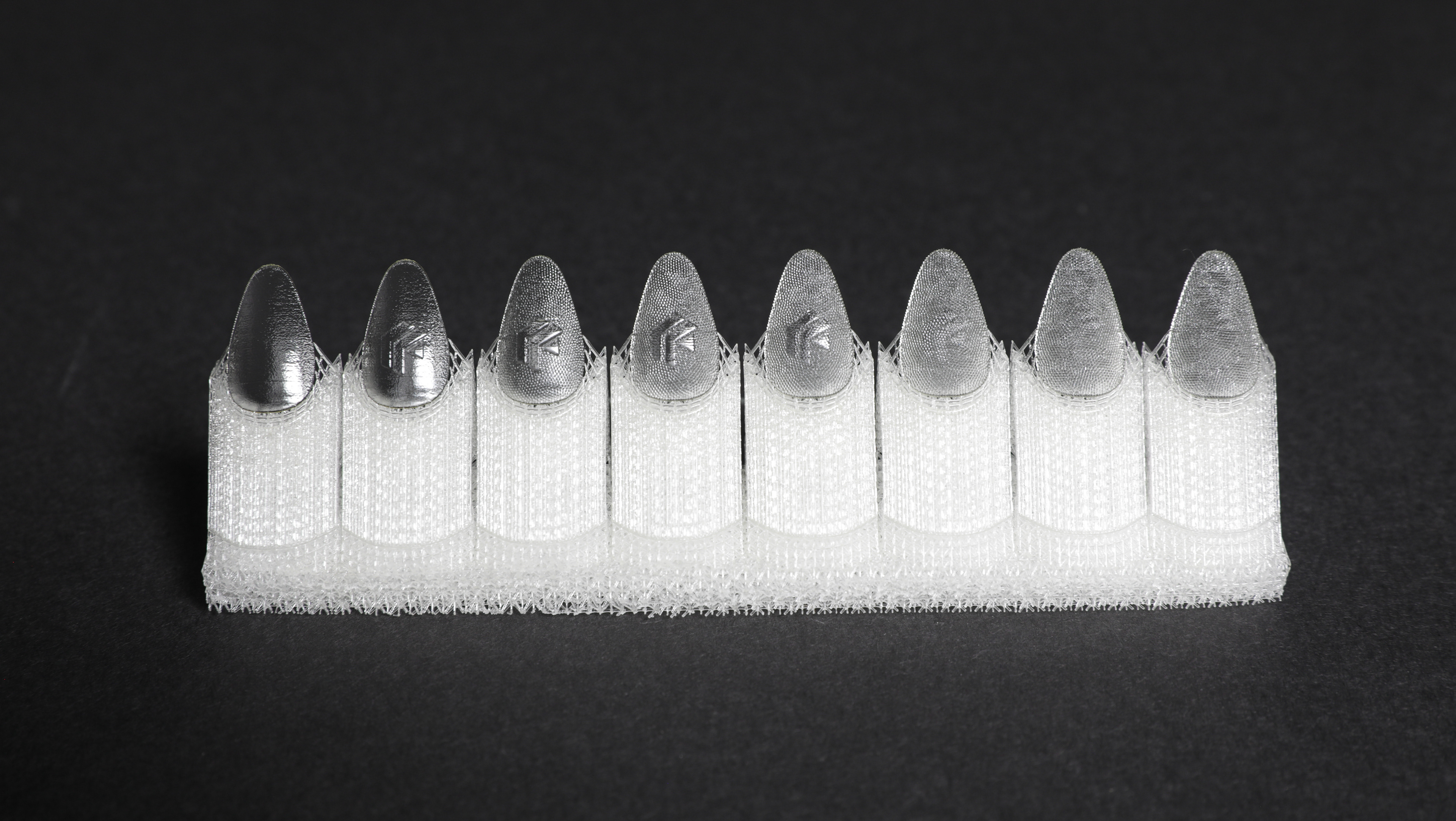

WHEELS - 328cm3, 5.4h print time, $39 part cost. Designed to accommodate heavy radial and lateral forces repeatedly and extensively. P3 technology produces parts with high accuracy and repeatability, ensuring bearings and exterior rubber tires fit perfectly on every wheel.

STEM BASE - 314cm3, 8.36h print time, $83 part cost. Designed to withstand strong torque and impact. Tappable Dura56’s strength allows for multiple screws and bolt connection points Printed without supports or polishing with the Origin One.

STEM BASE - 314cm3, 8.36h print time, $83 part cost. Designed to withstand strong torque and impact. Tappable Dura56’s strength allows for multiple screws and bolt connection points Printed without supports or polishing with the Origin One.

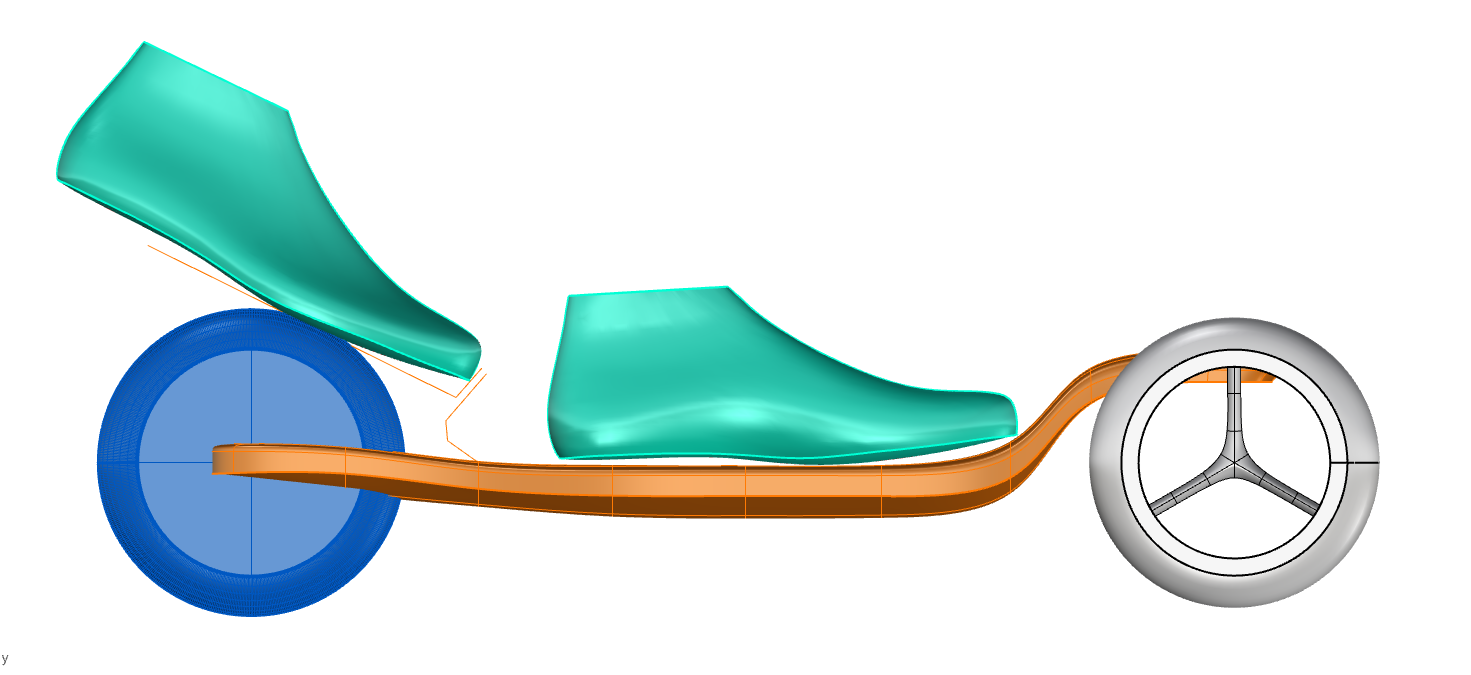

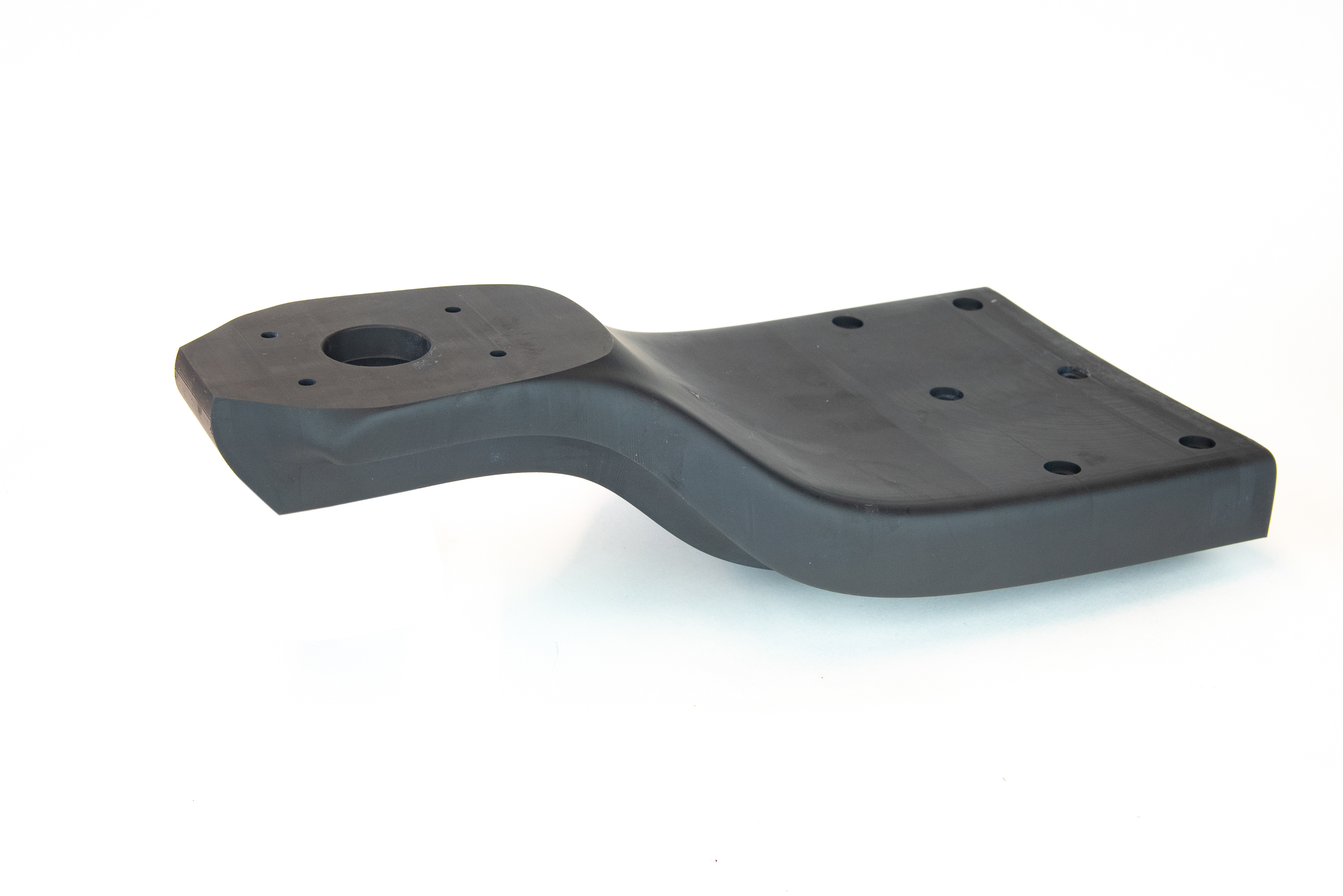

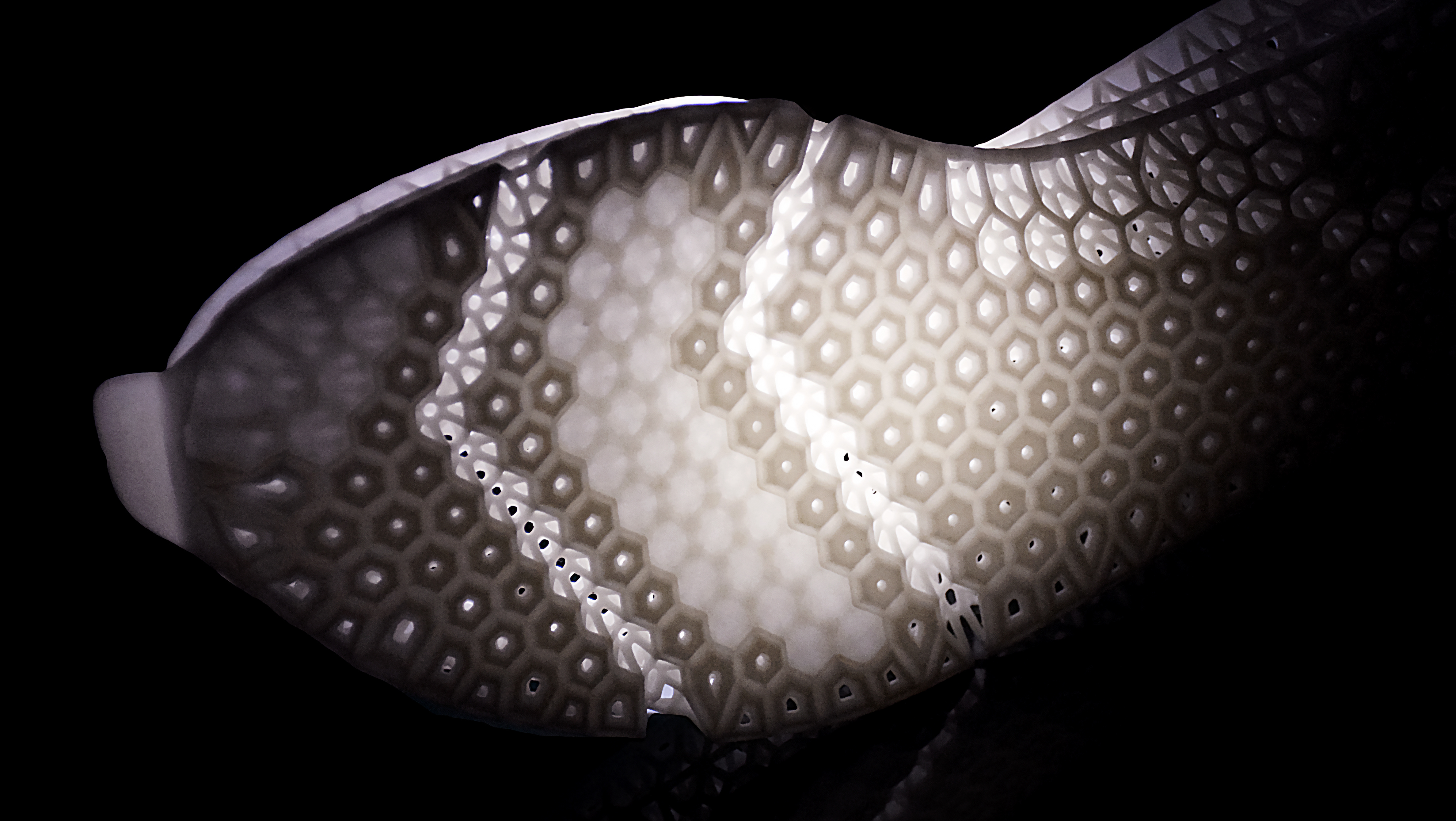

FRONT DECK - 1370cm3, 15.2h print time, $226 part cost. The central piece connects the steering column and front-wheel trucks and supports the rider’s weight. Origin One prints have high green strength, enabling easy production of lattices and overhangs.

BACK DECK - 1469cm3, 15.4h print time, $227 part cost. Secures back wheel with metal bearing and mates to the front of deck with 6 socket cap bolt and barrel nuts and 3 struts and slots, made possible by strong, durable, tappable Dura56 material.

The high-impact material we were testing inspired us to think of a strong animal that moved quickly and could take on large forces so naturally, we settled on a Spanish bull. The handlebars also pay homage to the shape of the horns while also taking on an ergonomic feel for the user to know to learn the system to be similar to a y-glider and a road bike combined.

Process Images