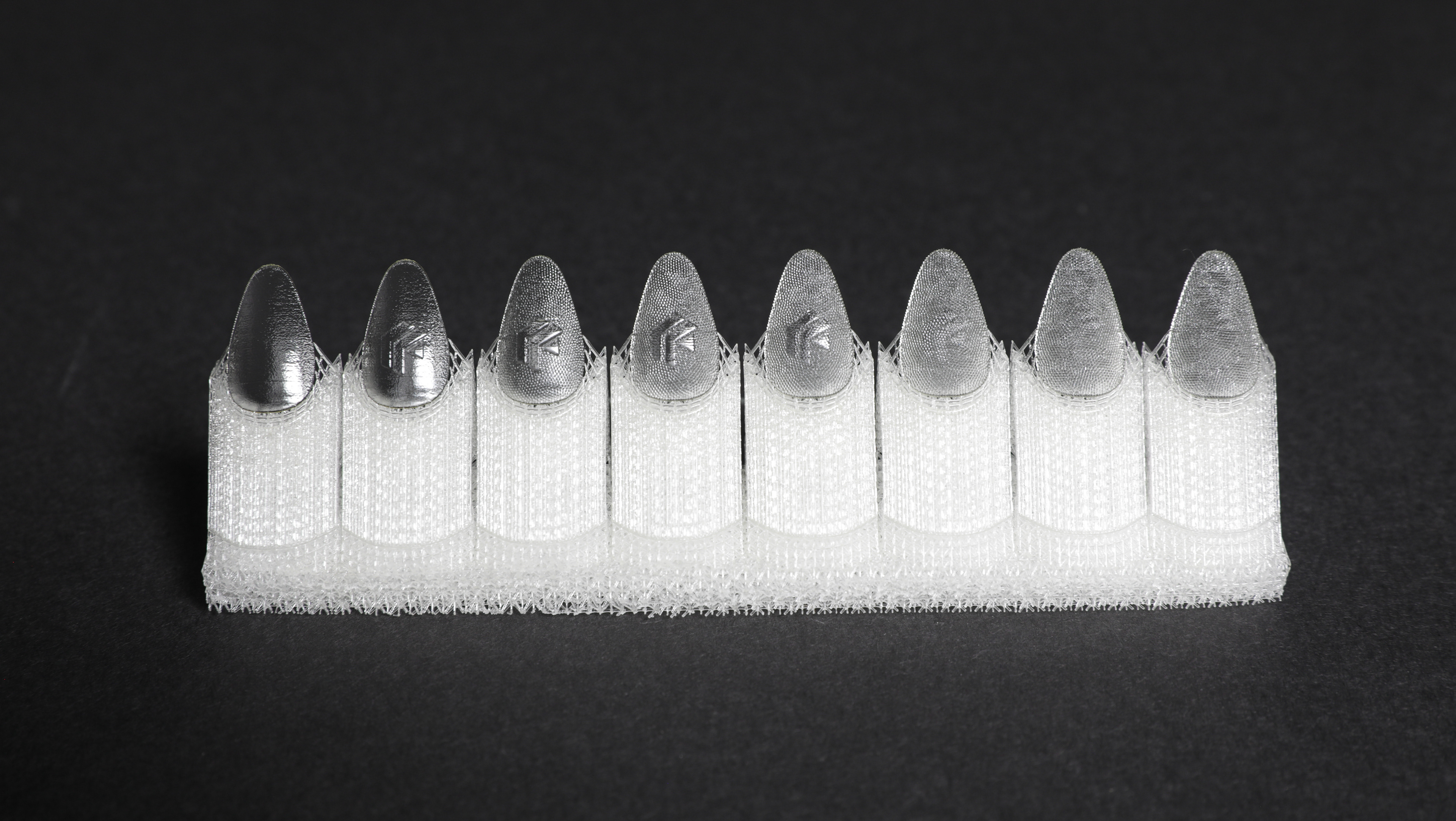

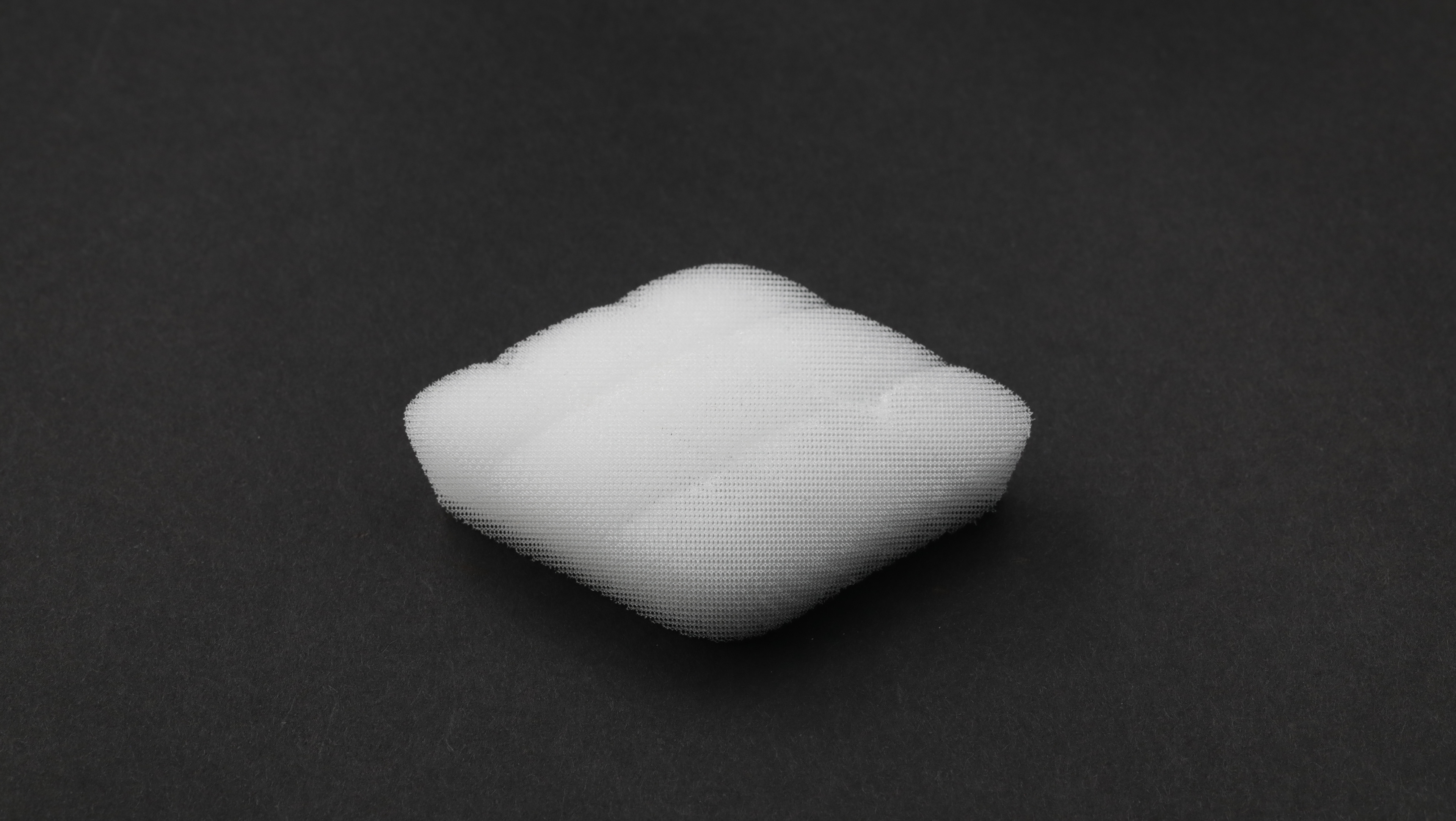

After getting back into skating, one of our founders was inspired to create something different and tailored to the type of skating he was looking for. Using nTopology, we were able to utilize topology optimization for lightweighting and enable a design that can be mass-produced specifically for additive manufacturing. To be able to withstand the extreme load conditions experienced during skating such as hard turning, jumping, and grinding on hard surfaces, FEA tools were used to create the topology-optimized solution that generated a structural geometry. In the areas between the wheels where less structure was needed, a strategic gyroid system was cohesively integrated within the structure openings.

The HP full-color printer used, Jet Fusion 580, allowed for the ability to have any motif and color pattern which really opened up the possibilities for the overall look. We worked on 2 looks: (1) Marble texture to match the Danny Beer THEM Skate, the other using nTopology advanced boolean operations to use the gyroid pattern as a color pattern. The PA-12 material used for the final product is durable, tough, and impact-resistant, targeting functional applications that need to perform under stress and high-load conditions. It is used to produce parts that require high stiffness with a good surface finish.

Additionally, thanks to the customizability of the design, we’ve developed multiple models that could adapt to different skating styles. As we continue to test out these designs, we envision creating many more unique color patterns and textured surfaces that could lend well to more interesting-looking skates. We will also be making files available for free online for people to print themselves and test out.

Learn more about our design process for this project on Duann Scoot’s DfAM Substack.

Files are available for download here.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.